Understanding Calcium Hardness

Reader note: An edited version of this article originally appeared in the summer 2007 issue of The Edge, a publication of the Northeast Spa & Pool Association.

Calcium hardness must be actively managed—along with pH and total alkalinity—to keep water in proper chemical balance. Current industry standards call for maintaining calcium hardness in the ideal range of 200–400 ppm in pools and 150–250 ppm in spas.

The Role of Calcium Hardness in Water Balance

While hardness in water consists of both calcium and magnesium salts ("total hardness"), only the calcium component is relevant in the water balance calculation for pools and spas. Called the Saturation Index (SI) formula, it considers the interrelationships of four chemical factors—calcium hardness; pH; total alkalinity, as corrected for the contribution of any cyanuric acid stabilizer in use; and, to a much lesser extent, the total dissolved solids level—plus one physical factor, water temperature. All but the mathletes among us use a water balance calculator like Taylor Technologies' Watergram® to do the number crunching involved. The value one arrives at reflects the water's degree of saturation with calcium carbonate.

When the SI value is zero, the water is properly balanced. Its calcium hardness, pH, and total alkalinity are acting in harmony with one another. When the SI is +0.5 or more, the unbalanced water is trending toward scaling, meaning conditions are right for calcium carbonate to come out of solution and deposit on surfaces as "scale." When the SI is -0.3 or less, the unbalanced water is trending toward corrosivity. Corrosive water attacks plaster, concrete, grout, and metal, resulting in etching, pitting, and surface stains and/or colored water caused by metal pulled out of piping, fittings, and equipment.

Can damage from scaling water be reversed? By reducing the SI to around -1.0 for a short time (usually by lowering pH), some calcium deposits in the filter and circulation piping can be dissolved, and the water's flow may even remove chunks of loosened scale. But this will come at a price. A thin layer of the concrete surface of the pool may dissolve as well, and copper can be lost from piping and/or heat exchangers.

Damage from corrosive water cannot be reversed, only repaired by resurfacing the concrete and replacing piping. Colored water can be cured with a "metal out" product, or chelating agent, and some of these are reportedly successful at removing certain surface stains.

The Effects of High and Low Hardness

Specifically, water with high calcium hardness gets cloudy unless the alkalinity and/or pH are low enough to compensate. As mentioned, the excess calcium carbonate will precipitate as crusty, grayish white scale on surfaces, piping, and equipment. It's unsightly, can cause abrasions on users and snag bathing suits, and makes a good anchor for microorganisms. It will clog filters. When it builds up in piping, circulation is reduced and pressure increases. Scaling is an especially acute problem in heaters because calcium's solubility is inversely proportional to temperature: As temperature increases, less calcium is able to stay dissolved. Scale on the pipes or coils acts as an insulator, slowing heat transfer. This makes it more expensive to heat the water. Over time, thick scale will cause a heater to fail.

Water with low calcium hardness will seek more by dissolving it from surfaces it comes in contact with that contain calcium, such as plaster, grout, and concrete decking. The late Dr. Neil Lowry, a well-respected instructor in our industry, preferred to call water with low calcium hardness "aggressive" rather than "corrosive" because the latter term implies the destruction of metals. The corrosiveness of unbalanced water, he would tell his students, comes from poorly maintained alkalinity and pH.

| Calcium Hardness Too Low | Calcium Hardness Too High |

|---|---|

|

|

|

|

|

|

|

|

Testing

To avoid damage to pools and spas from unbalanced water, test calcium hardness at least monthly. Calcium hardness is best monitored with a drop-count titration, as test strips can only measure total hardness. In addition, whereas test strips for total hardness have just four or five color blocks to cover a tremendously wide range—from 0 to 1,000 parts per million (ppm) with color blocks for 0, 100, 250, 500, 1,000, for instance—a drop test will allow you to approach the true concentration of calcium hardness in 10 ppm increments. This means if you're faced with wanting to balance water in a spa by increasing the calcium hardness from 60 ppm to 150 ppm, the strip can't help but the drop test can.

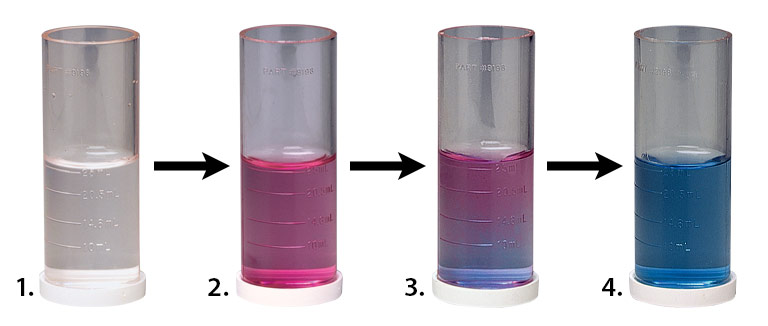

To perform a drop test, simply fill a test cell with sample water, add buffer and indicator reagents, and swirl to mix. The sample will turn red if calcium hardness is present. Next, add the calcium hardness reagent, swirling and counting each drop, until the color changes from red to blue. Finally, multiply the number of drops used by the equivalence factor in the test instructions to determine the calcium hardness level. The reading is expressed as parts per million as calcium carbonate.

Note: retailers with water-testing stations may find that using a countertop laboratory with a built-in magnetic stirrer speeds up performance.

The color progression in a hardness test is from red, to a mixture of red and blue, to blue. To be certain the color change is permanent, indicating you have reached the true endpoint, add one more drop of titrant. If the blue color remains unchanged, do not count this drop.

Beware the Fading Endpoint

Occasionally when testing calcium hardness you may get a purple endpoint instead of blue. This is called a "fading endpoint" and is due to interference from metal ions (most likely copper from algaecides, pipes, or source water). Retest, but prevent the interference by adding five or six drops of hardness reagent to the sample before adding the buffer and indicator. Then proceed as usual. Remember to count the drops of titrant added at the beginning when you calculate the total number of drops required to reach the endpoint.

Adjusting Hardness

You can raise water's calcium hardness easily by adding calcium chloride (CaCl2). Two forms are sold: hydrated (77% strength) and anhydrous (100% strength). Each will generate heat when contact with water is made. Therefore, generally you are instructed NOT to pre-dissolve the calcium chloride in a bucket, but to broadcast it over the water's surface with the pump running. Adding calcium chloride in the hours before or after treating with soda ash (sodium carbonate) or baking soda (sodium bicarbonate) will result in cloudy water.

To decrease calcium hardness, you must partially drain the vessel and refill it with lower-hardness water. Unless pH and alkalinity are already low, however, it will often be more practical to adjust the Saturation Index by lowering these two factors through the addition of acid than to replace water. This would certainly be the case where drought has caused limits to be placed on water used for recreation.